Fieldbots Fleet Management

Deliver cleaning results with FieldBots Operate and Maintain

Our manufacturer-independent fleet management consists of FieldBots Operate, Maintain and Connect. It empowers you and your team to manage the daily operations of your distributed fleet, supports your technical team’s maintenance processes, and ensures roles, rights and connectivity are in place. Based on the group’s 15 years of cloud and app experience in the FM industry and ten years in FM robotics, we built our apps and cloud for thousands of robots.

Why FieldBots

Our approach covers the entire lifecycle.

Customer-centric

Service delivery to the customer comes first

Advice

Reach your ROI and make your fleet grow

Reporting

Clear reporting on delivery, utilization, and sustainability

All platforms

Fully featured for desktop, mobile, and tablet

Intelligence

Technicalities are managed in the background

Distributor access

Allow your service partner to offer direct support

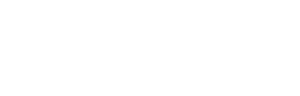

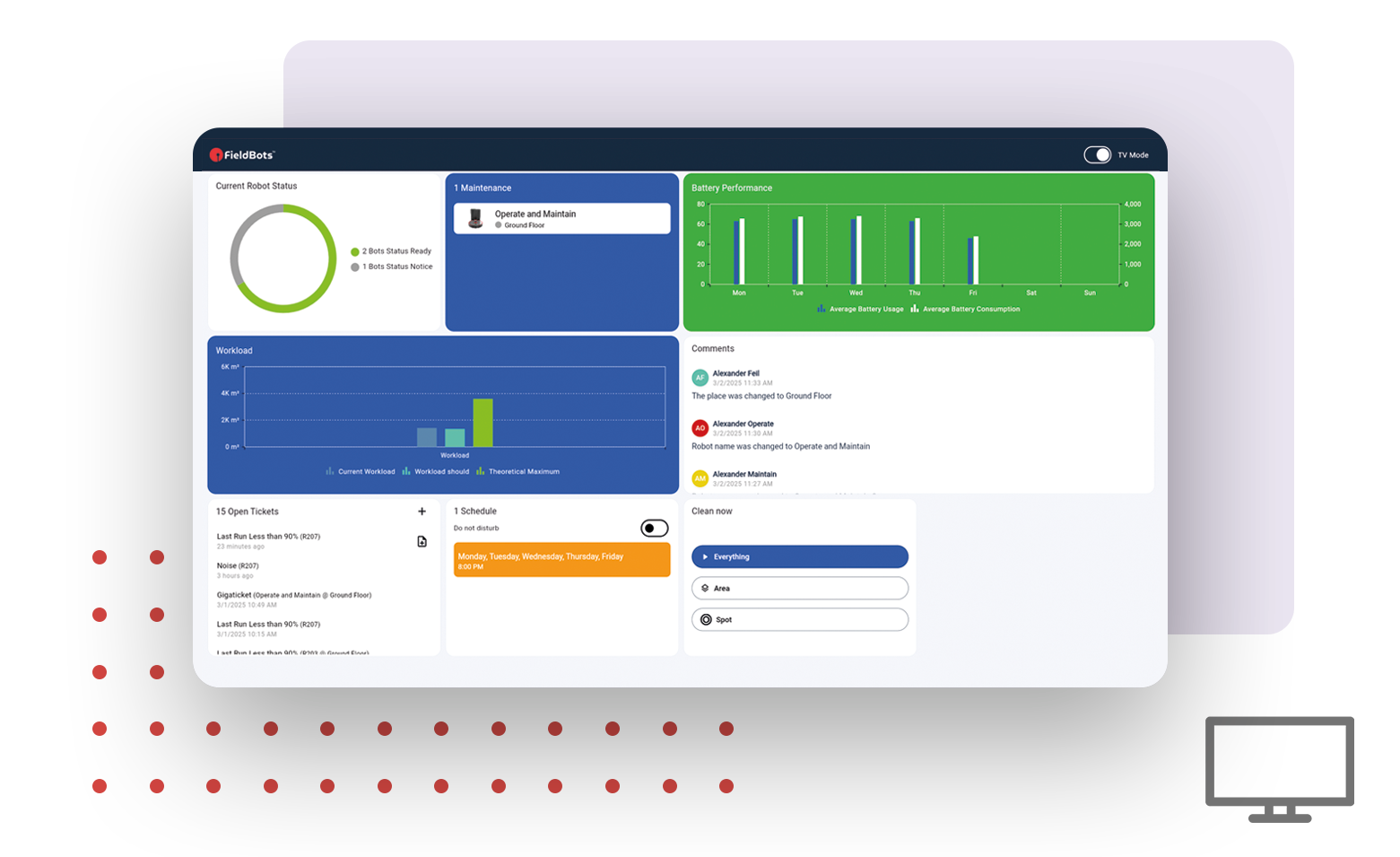

APPS

Equip Your Operations Team

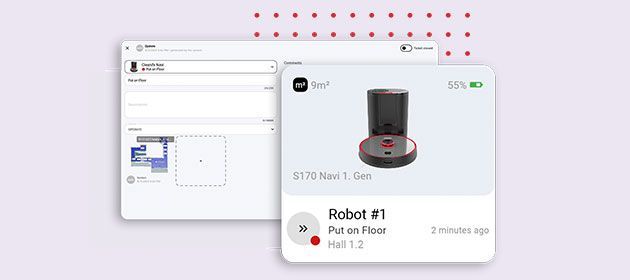

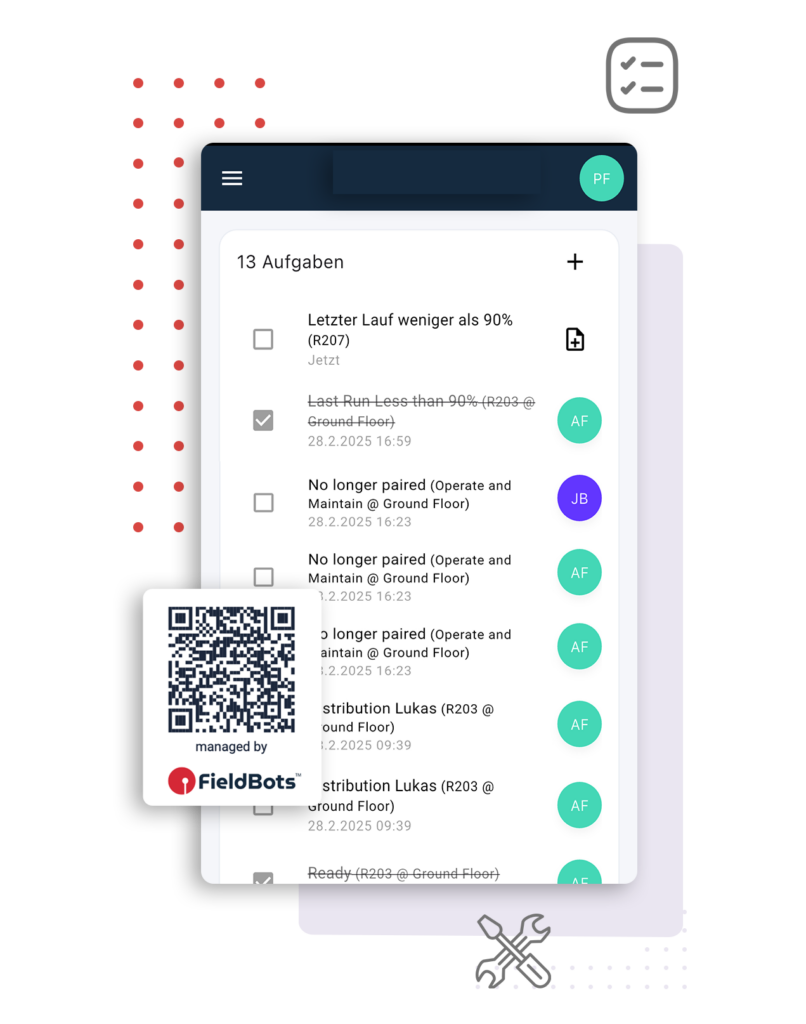

Our smartphone and tablet apps for iOS and Android ensure that your operations team can focus on service delivery. Scan the FieldBots QR code, check the robot’s status or leave a comment.

Key features

- Live maps and status

- Cleaning history and comments

- Service delivery alerts and push notifications

- Scheduling and do not disturb

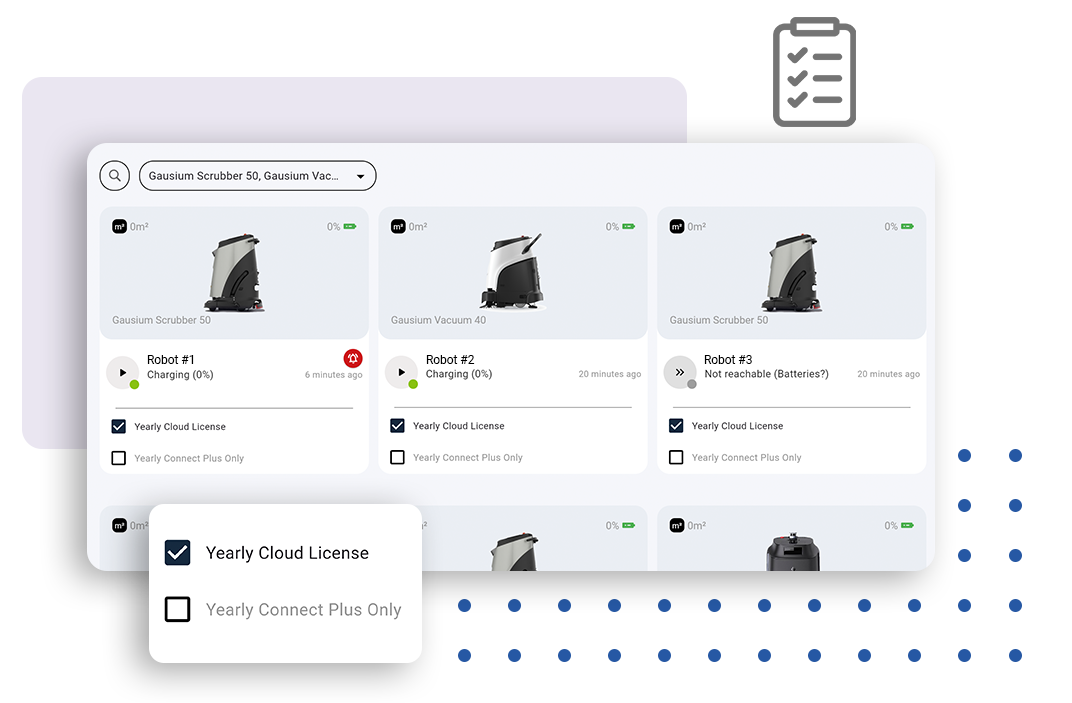

MAINTAIN

Keep Your Fleet Maintained

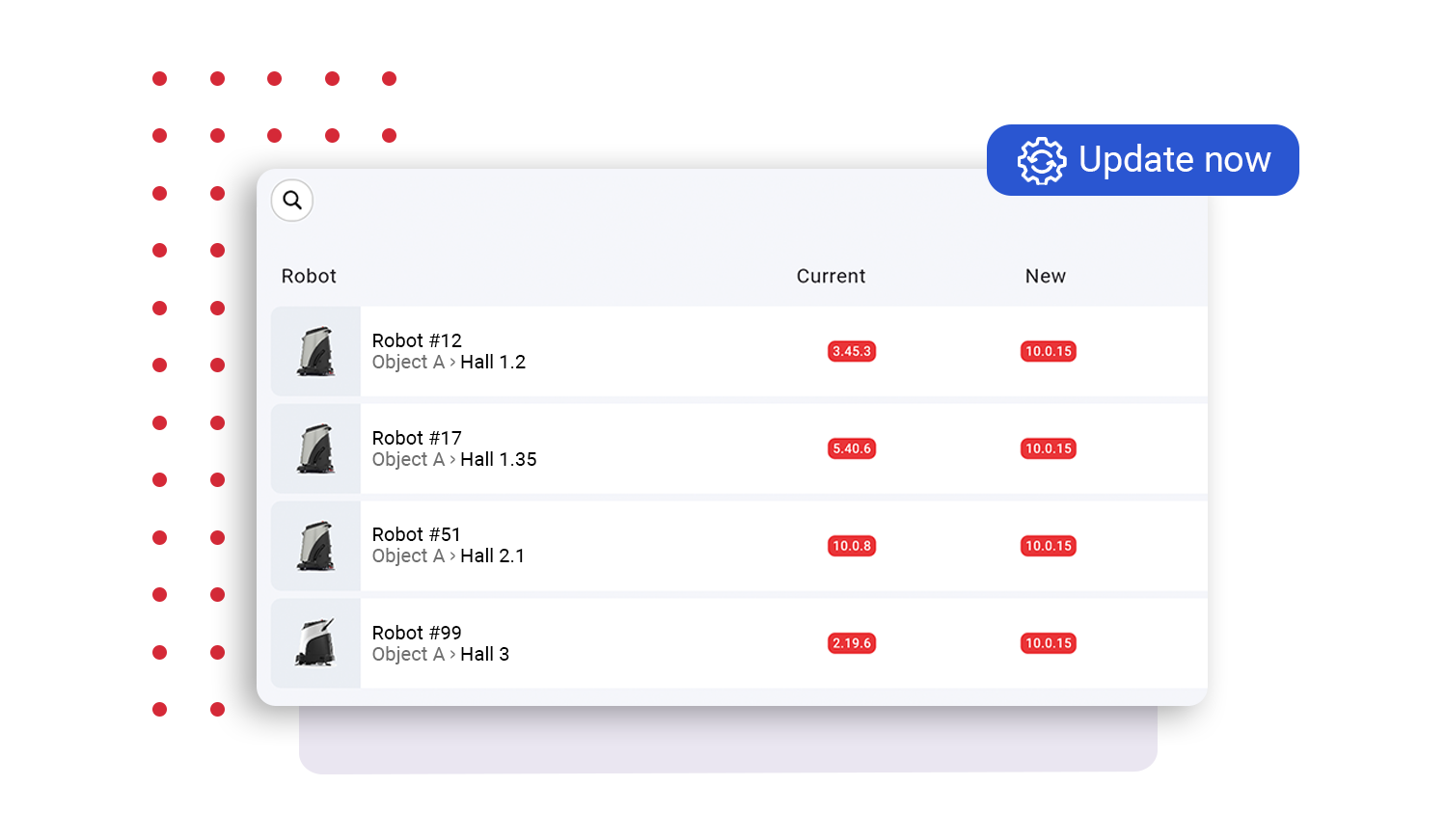

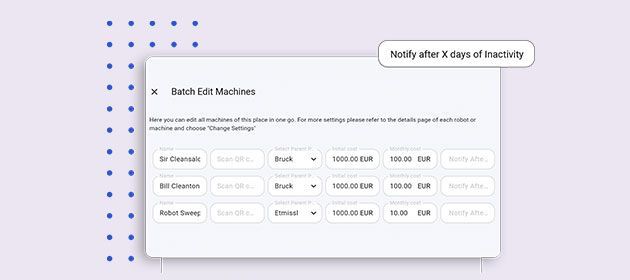

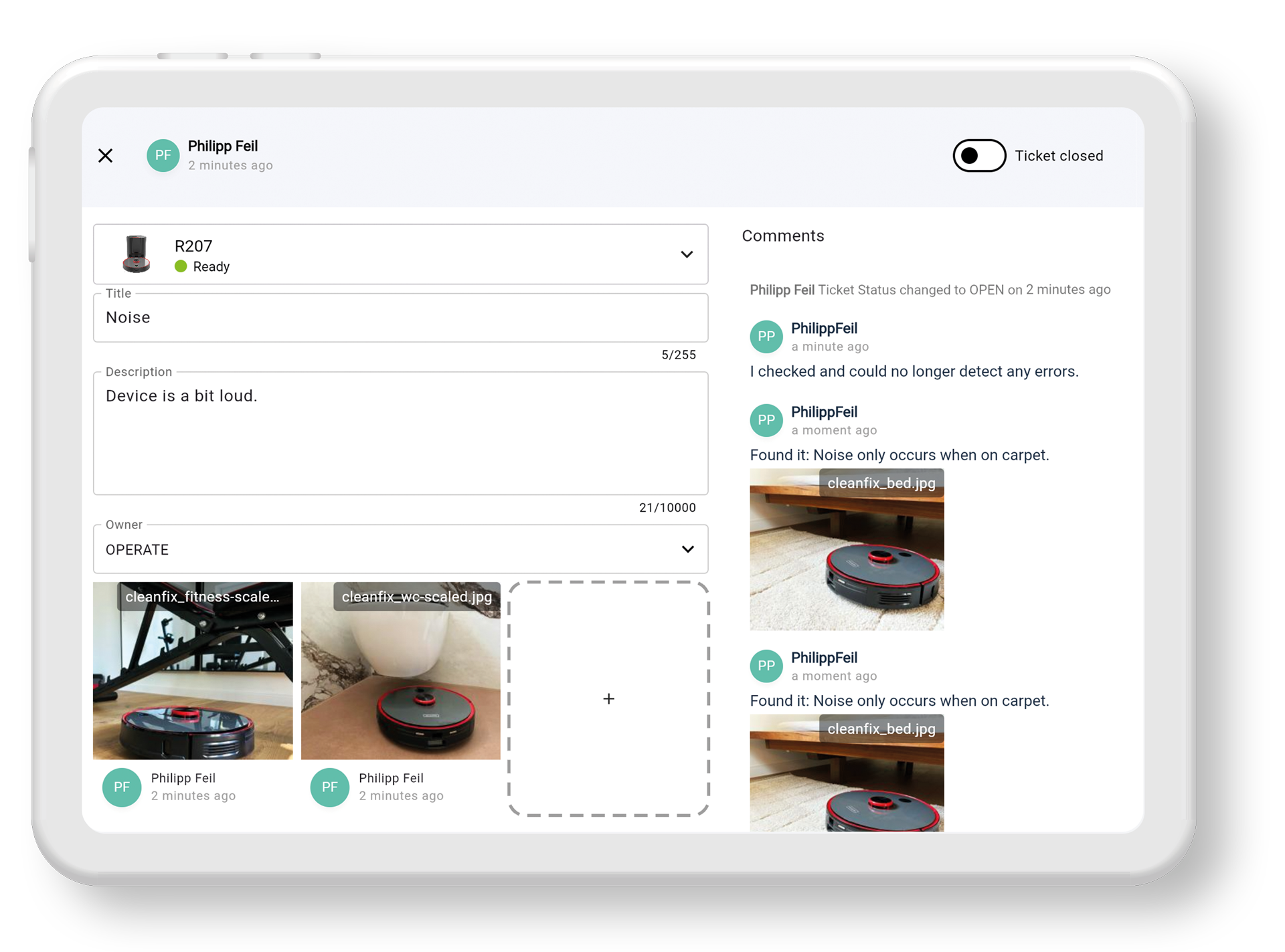

FieldBots Maintain keeps your operational and maintenance teams in one tool yet ensures that technical topics stay out of the way of operations. Based on your robots’ rich data FieldBots collects, you can analyze parts of the fleet that need your attention and track tasks with our built-in ticketing. Keep all documents attached to your tickets and robots, use our shop for microbot consumables, and manage FieldBots licenses in one place.

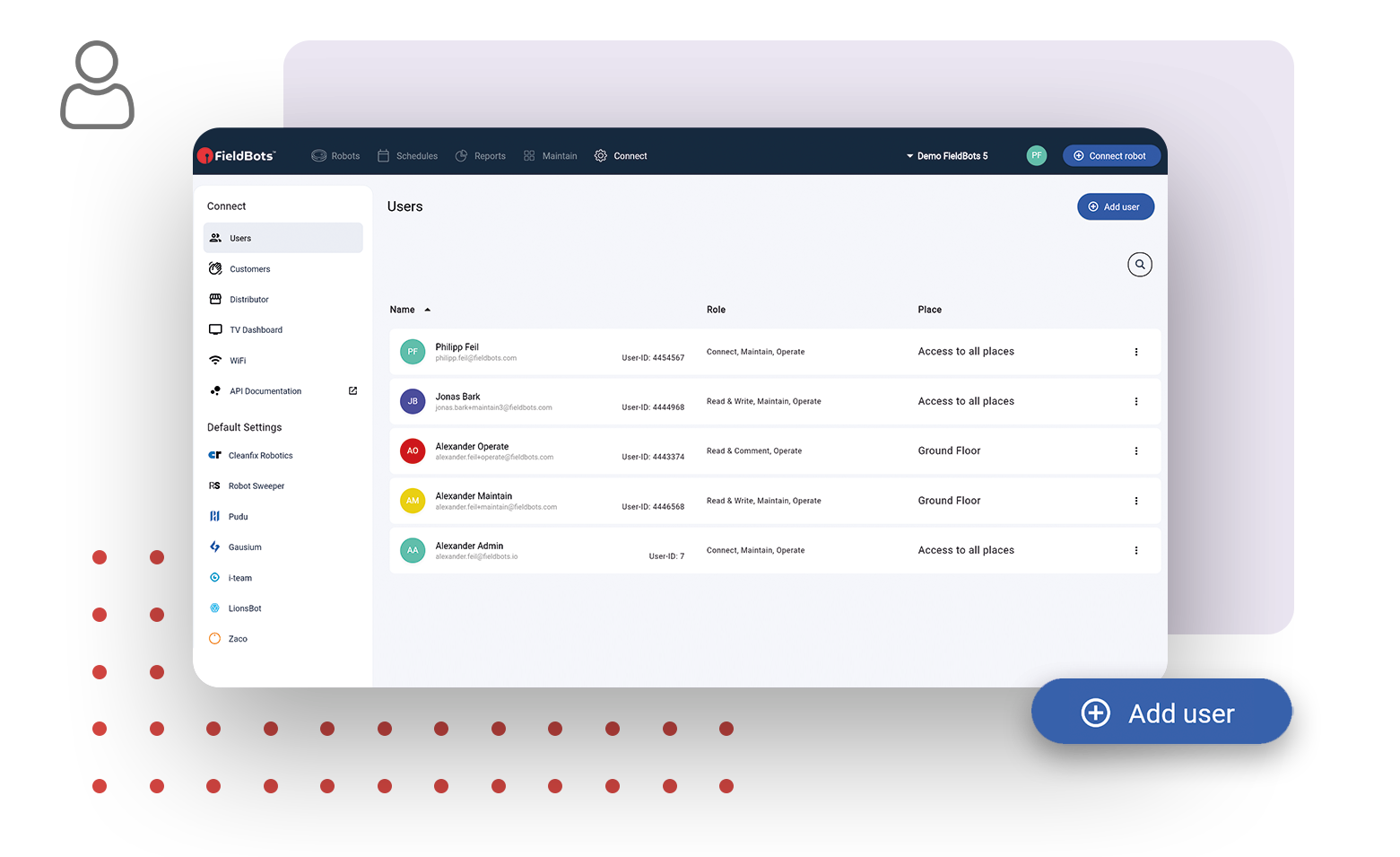

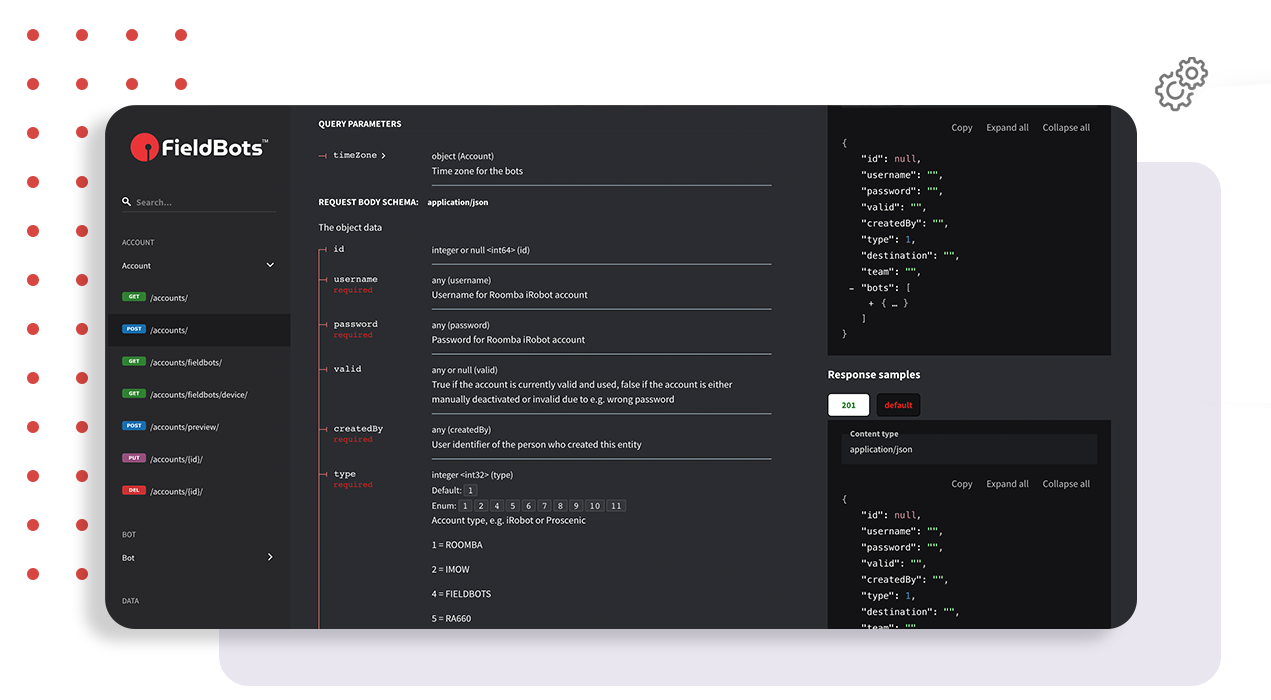

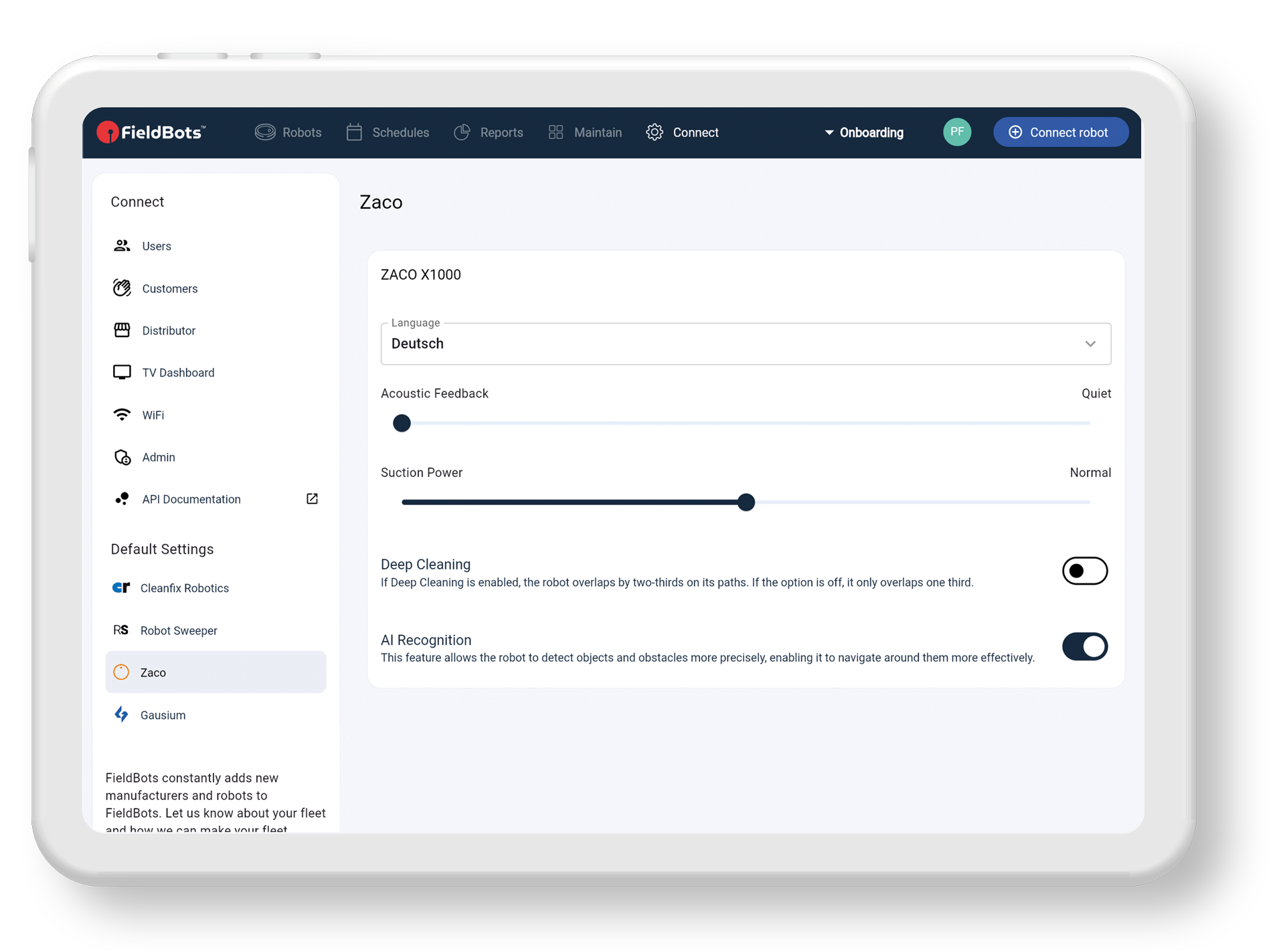

CONNECT

Bring All the Sources Together

FieldBots Connect is the connection point for your microbots and the robots FieldBots accesses via manufacturer clouds. Furthermore, FieldBots Connect is your key to bringing your team up to speed: add as many users in different roles and with varying access levels as you want, make your distributor join if you need it, and even invite your customers. Manage all the manufacturer connections and even plug in your TV for a live status dashboard.

OUR CEO GUIDES YOU THROUGH FIELDBOTS 6

What’s New in Fieldbots 6?

With the release of FieldBots 6.0, we’re opening an entirely new chapter in fleet operations. Watch our CEO, Alexander Feil, as he walks you through the powerful new tools that await FieldBots users and explains how FieldBots Intelligence is changing the way robotic fleets are managed.

Physical Intelligence

Physical Intelligence is the direct loop between the cloud and the real world. FieldBots learns from robots operating in material environments and acts back on that hardware. Rather than only showing telemetry, this layer interprets behavior, coordinates devices, and enforces fleet-level rules so that decisions grounded in hardware realities can be executed automatically.

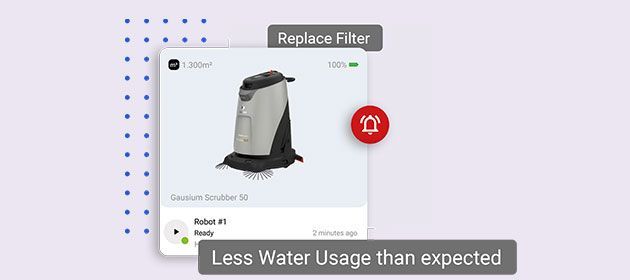

Behavior Watch

An abstract layer of behavioral awareness beyond the robot firmware. Behavior Watch evaluates performance metrics such as water usage, energy consumption, and cleaned area yield. Deviations from expected behavior are translated into proactive alerts so operators can intervene before inefficiency becomes downtime.

Elevator Coordination

A universal integration layer between robots and elevators. Elevator Coordination removes integration friction across countless robot and elevator manufacturers by providing a vendor-neutral bridge. With our KONE collaboration in DACH regions, distributors and integrators can coordinate vertical mobility without custom engineering for every device.

Combined Maps

A single operational map built from live maps of Level 3 integrated robots. FieldBots merges per-robot maps into a comprehensive floor plan so operators can draw virtual walls and no-go zones across devices and areas. The fleet moves from isolated mapping to a unified spatial intelligence.

Big Data Intelligence

Big Data Intelligence harvests crowd-sourced data across the FieldBots Cloud to create benchmarks, financial projections, and lifecycle estimates. Anonymized comparisons reveal how a fleet or model performs against the global population and expose optimization and commercial opportunities operators could not see from isolated data alone.

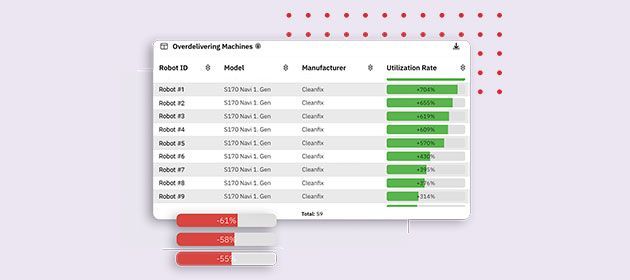

Robot Utilization Benchmarks

Performance through comparative context. Utilization Benchmarks show whether a robot is being used to its potential relative to the same model across the global FieldBots network. Outperformance indicates optimal deployment; underperformance points to immediate improvement areas.

ROI Calculations

Real performance translated into real money. ROI Calculations combine acquisition cost, operating cost, runtime, and pricing per square meter or square foot to project break-even points for individual robots, sub-fleets, or entire operations. The output is a time-based profitability view for managers and customers.

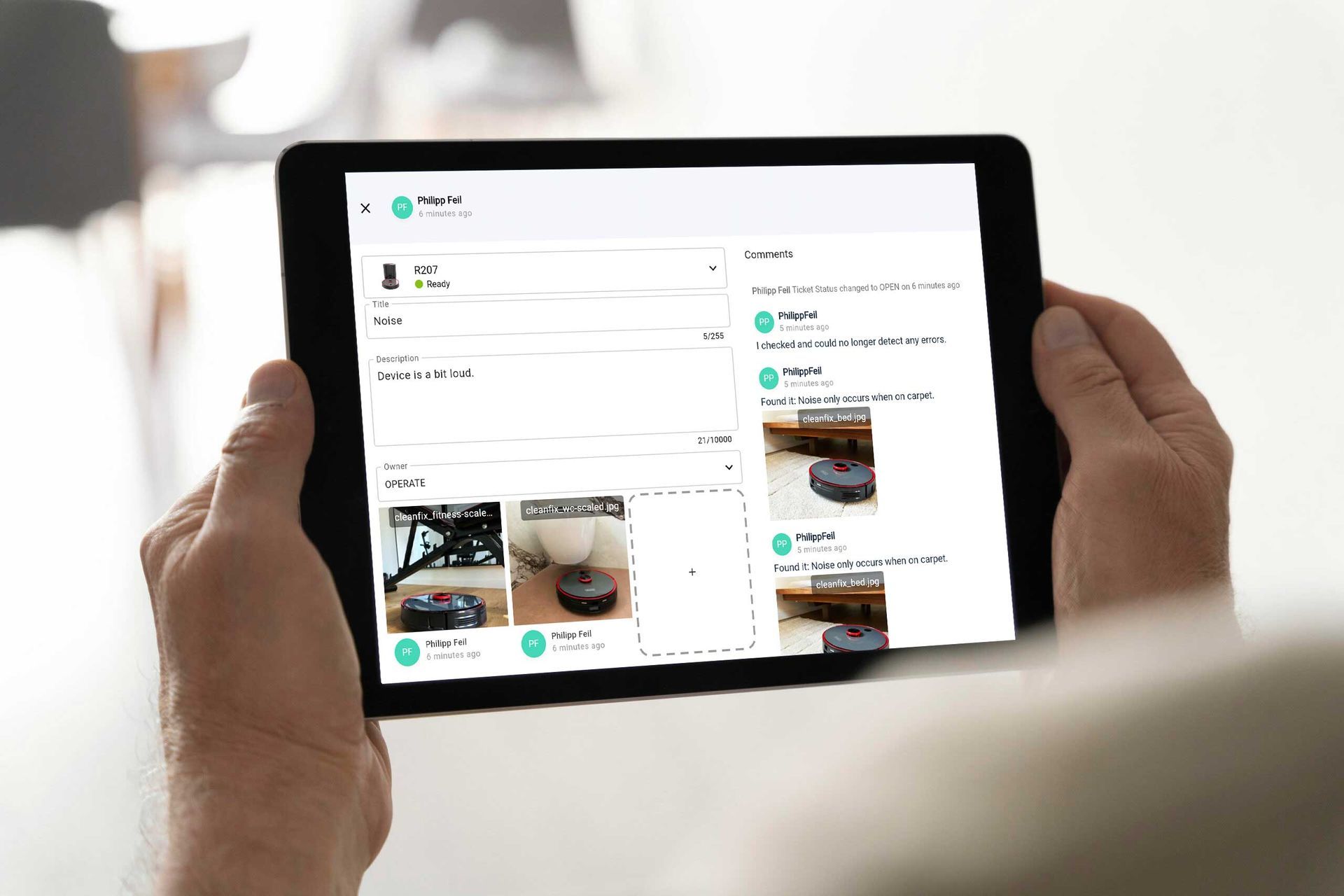

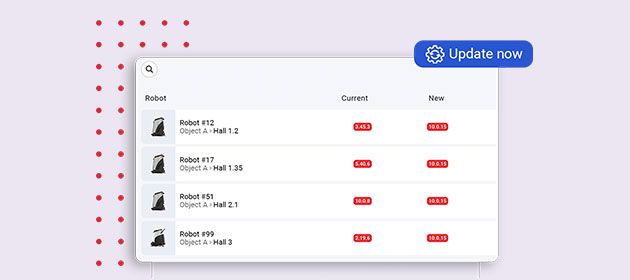

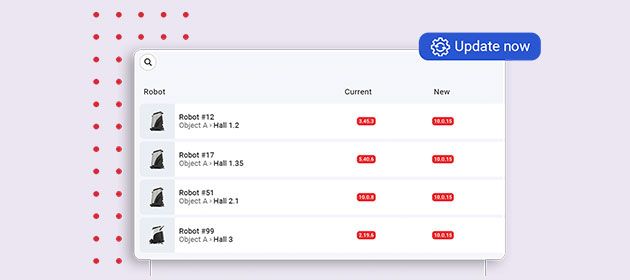

Firmware Radar

A global view of firmware health and drift. Firmware Radar maps firmware versions across models and operators, surfacing experimental, current, and outdated releases. This visibility supports security, navigation quality, and access to newly unlocked features for purchased hardware.

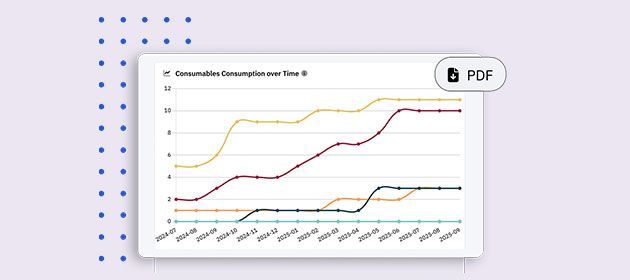

Consumable Lifetime Estimates

Predictive wear analytics for consumables. By correlating runtime with recorded replacements, FieldBots estimates lifetimes for brushes, squeegees, suction lips and similar parts. These estimates enable more accurate costing, reduced waste, and stronger ESG and sustainability reporting.

Agentic Intelligence

Agentic Intelligence is the first practical step toward fleets that manage themselves. It harvests signals from Physical and Big Data Intelligence to propose or, where authorized, perform actions on behalf of operators. Opt-in controls keep human oversight in place while enabling automated workflows that scale.

Tickets for Stuck Robots

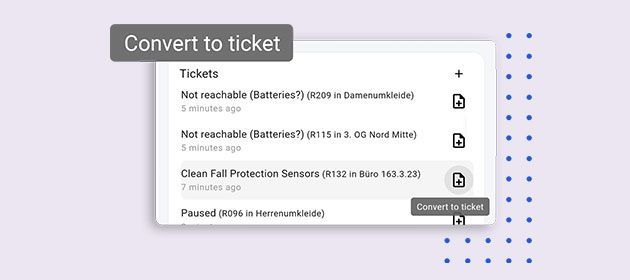

An agent that files tickets automatically when a robot reports it is stuck. Each ticket includes a map snapshot at the reported location so teams can diagnose repeat failure points even if the robot has been moved. The feature makes recurring obstructions visible and actionable.

What’s Next Suggestions

A proactive maintenance assistant. The agent watches status changes and usage patterns, then suggests targeted actions for maintainers — for example, reconnecting a lost device, performing an immediate repair, or scheduling preventive work. Suggestions can be converted into tickets with one action.

Auto-Update Robots

Automated, timely firmware updates. Building on Firmware Radar, this agent can trigger firmware rollouts at low-impact times for Level 3 integrated robots, or request updates via the designated dealer. The goal is to keep fleets on the most secure and capable software state without manual coordination.

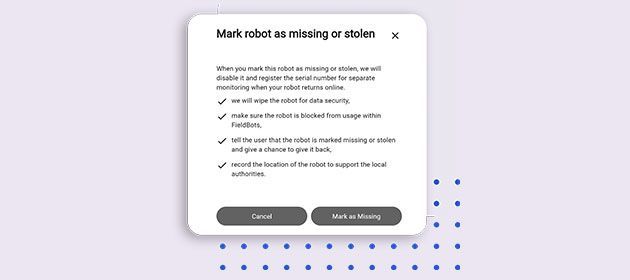

Watch Missed Robots

A recovery and security monitor. Robots marked lost or stolen are monitored for any subsequent reconnection attempts. If a device appears again, the agent captures location and connection metadata for recovery or law enforcement follow-up and halts unauthorized reconnection until validated.